Technology

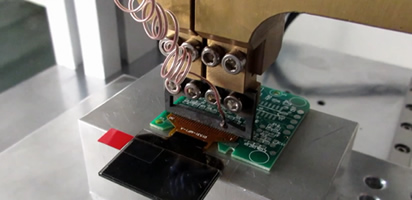

1Clicksmt Hot bar reflow soldering is extremely effective in bonding components and parts that are difficult to unite. it uses thermode technology, which is based on rapid reflow by pulse heating. It selectively solders parts by heating them to a temperature that's high enough to cause their adhesive or solder to melt and then re-solidify to form a permanent bond.

- Home

- Technology

Soldering pad design request

Soldering pad design request for hot bar soldering machine

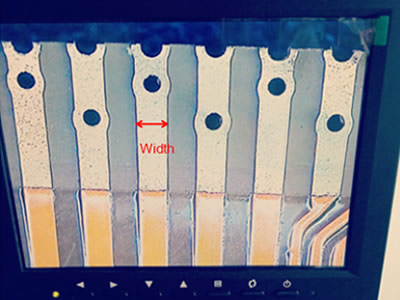

1. The width of the pad need more than 0.3mm.(Suggestion:0.5mm)

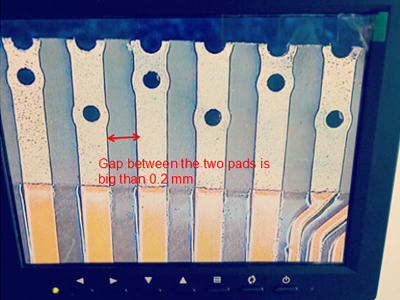

2. The gap between two pads need more than 0.2mm.

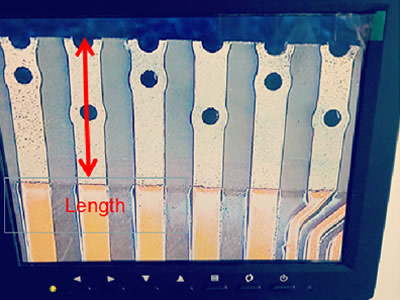

3. The length of the pad is ≧3mm.(Suggestion)

4. The height of the component near the pad no mre than 8mm.(Within 4 mm around the pad)

5. On the FPC board, Both two side have soldering pad.(Better heat transfer)

6. The distance between the soldered area and the unsolder pad is greater than 1mm.(Prevent soldering from affecting soldered areas)

7. The recommended diameter of the soldering hole on the pad is 0.2mm.

8. Tin is required on the pad of the product.

refer pic 1

refer pic 2

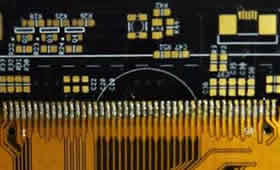

refer pic 3-8

Hot Bar Soldering System

The Hot bar soldering machine is mainly used for soldering operations on devices that cannot be soldered using a normal SMT+ reflow soldering. However, when soldering iron is used for soldering, it is prone to inconsistent and uneven soldering appearance, easy to appear virtual welding and easy to damage the soldering pad. The pulse hot press is different from the constant temperature soldering iron. The pulse hot press can reach the required temperature at the moment of energization, and once the voltage is not applied to both ends of the welding head, it can reach the room temperature instantaneously; and the soldering tip is flat, so the appearance of soldering the level is uniform and there is very little bad solder joint.

Manual solder

Machine solder

Principle of Soldering

Hot bar soldering machine principle of soldering

By loading a certain pulse voltage on the Soldering tip, the Soldering tip heats up, and the FPC and the connected object heat up. When the temperature rises to the melting point of the solder (ie, rises to a preset temperature), the PFC is connected to the object. The tin melts and connects them together. A typical pulse hot press uses temperature closed loop control.

[Learn more Video]

Good Soldering Quality

How to ensure soldering quality stability?

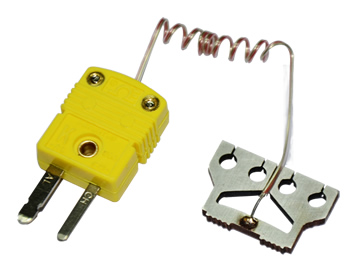

Soldering tip heats up to be uniform

Our hot bar soldering machine's soldering tip is made of molybdenum alloy with stable welding temperature and long service life.

The position of the soldering tip needs to be balanced

Our hot bar soldering machine has fine adjustment knobs for up and down position, which can precisely adjust the balance of the soldering tip position. Ensure uniform pressure across the solder joints

Correct position of soldering position

The machine has a CCD display function, which can accurately align the products. Also the machine can be equipped with precision fixtures to fine-tune the soldering position back and forth and left and right.

The pressure of the soldering tip can be adjustable

Our hot bar soldering machine has upper and lower limit sensor detection. By adjust the sensor and the fine adjustment screw,that can be fine adjust the position accodring to the soldering pressure.

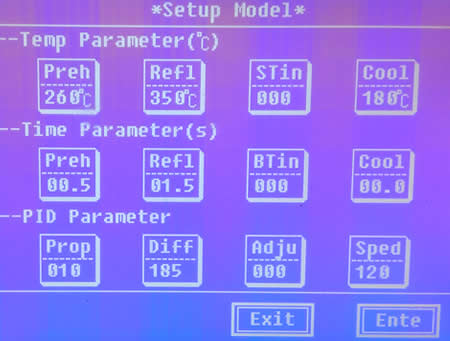

The machine has precise temperature control

The machine adopts PID control, precise temperature control, fast heating speed, and the machine has self-tuning function, which can self-tune according to different welding parameters, and set the most suitable compensation temperature value and PID value.

Machine soldering process is divided into 3 sections soldering temperature, preheating temperature, soldering temperature and cooling temperature to ensure that the product can be fully heated during the soldering process. The product can be quickly cooled after soldered to ensure the stability of solder joint quality.

The fixture cannot use a heat-conducting material

ESD synthetic stone is used on the upper part of the fixture to ensure stable temperature during soldering and heat conduction is not easy. Fully protect the product.

Copyright © 2025. 1clicksmt-hotbarsoldering. All Rights Reserved