Products

1Clicksmt can provide all kinds hot bar soldering machine. Provide a full range of soldering solutions. Economical hot bar soldering machine and high-grade hot bar soldering machine. There will always be a soldering robot suitable for customers' products.

Features

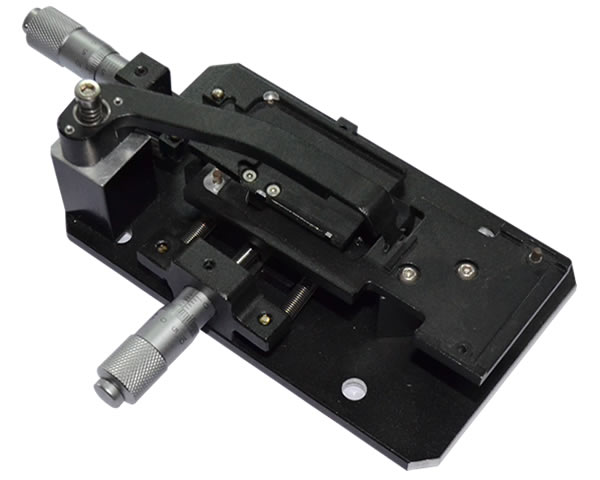

HBS-4AM Hot Bar Soldering Machine use thermode technology that based on repid reflow by pluse heating to effectively solder flexible board on the PCB. Real time display on the touch screen. Can use CCD+displayer can accurate positioning and soldering quality check. The Z axis is controlled by a stepper motor and can be preset to soldeing pressure. Double soldering station with high soldering efficiency. X/Y1/Y2/Z four combine axis. Soldering position can be programmed on the touch screen.

Double Station Hot Bar Soldering Machine HBS-4AM Features:

● In response to different products, the heating rate can be adjusted.

● Molybdenum alloy soldering tip ensures average temperature, fast heating and long life time.

● The soldering tip is specially designed with horizontal adjustment to ensure the average pressure of the components.

● Temperature control, clear and precise.

● With digital pressure gauge, preset pressure range.

● The X, Y1, Y2, Z all of them use precise step motor.

● Using precise PID control, phase angle instead of pulse drive.

● Low vibration, low noise, no voltage fluctuation.

● The soldering tip replaces the traditional titanium alloy with molybdenum alloy, which has fast heating and cooling, good heat transfer coefficient and wear resistance.

● Small size, push-pull left and right, two soldering stations can be placed to improve work efficiency.

● Height Z axis adjustable, accuracy is ±0.01mm.

● Precision step motor control, accurate and stable than traditional cylinder type.

● With pressure detection function, it automatically detects and adjusts the pressure to solve the problem of uneven force. We will replace the Z axis with a servo motor (Option)

Specification

| Double Station Hot Bar Soldering Machine HBS-4AM specification: | ||

|---|---|---|

| 1 | Machine dimension Size | L800*W720*H800mm |

| 2 | Working Area | Max 180*200mm *2pcs |

| 3 | Weight | Around 95kg |

| 4 | Air | 0.5~0.80 Mpa |

| 5 | Power | AC220V±10%50HZ.2000W |

| 6 | Temperature setting | 3section |

| 7 | Work Environment | 10~60℃,40%~95% |

| 8 | Soldering Pressure | 1~100N |

| 9 | Soldering Pressure Precision value | ±1N |

| 10 | Temperature Setting | RT∽500℃, (±2℃) |

| 11 | Heating Rate | 250℃/s |

| 12 | Soldering Time | 1-99.9S |

| 13 | Soldering Precision | Pitch 0.2mm |

| 14 | Soldering Head Size | Max 50*3mm (or customized) |

| 15 | Soldering Head Flatness | ±0.02mm |

| 16 | Soldering Pin Range | >0.2mm |

| 17 | Contraposition Mode | CCD+ Display |

| 18 | Material Placement Method | Manual |

| 19 | Start Mode | Hands |

| 20 | Heating Mode | Pulse heating, the rise time is 1~2S |

| 21 | Platform Moving Mode | Left/Right Platform (Signal X axis; Double Y axis) |

| 22 | Platform Control | Servo motor + screw, Accuracy<0.02mm |

| 23 | Pressure Soldering Output | Motor Drive (closed-loop control) |

| 24 | cooling method | Air cooling |

What options are available ?

Copyright © 2025. 1clicksmt-hotbarsoldering. All Rights Reserved